Hello friends, today we will explore various methods for taper turning on a lathe machine.

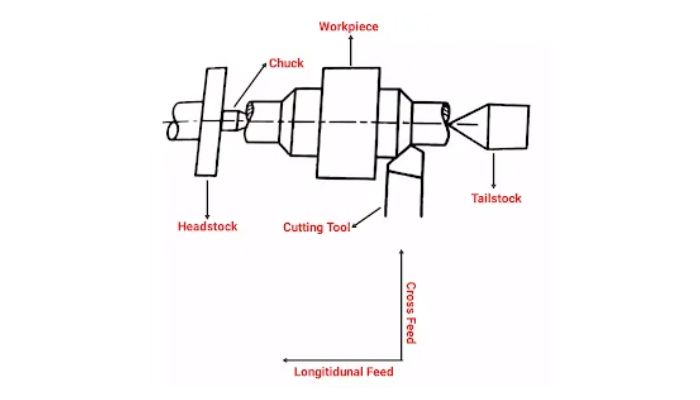

Before delving into the types of taper turning methods, it’s important to have a grasp of the lathe machine’s components and different taper types, as discussed in the previous post.

Without further ado, let’s delve into the various methods for taper turning on a lathe machine.

Types of Cutting Tool Materials and Their Properties

What is Taper Turning

Taper turning on a lathe machine involves cutting the metal in a manner that results in its surface forming an angle with the metal’s axis.

The following are the various methods to which taper can represent.

- According to the top angle of the taper.

- mm Per meter (mm / m).

- According to the diameter of each end of the taper and the length of the taper.

- By any ratio.

Types of Taper Turning Methods

The following are the different types of taper turning methods on lathe machine.

- Tailstock Set Over Method

- Compound Rest Method

- Taper Turning Attachment Method

- Form Tool Method

- Combining Feeds Method

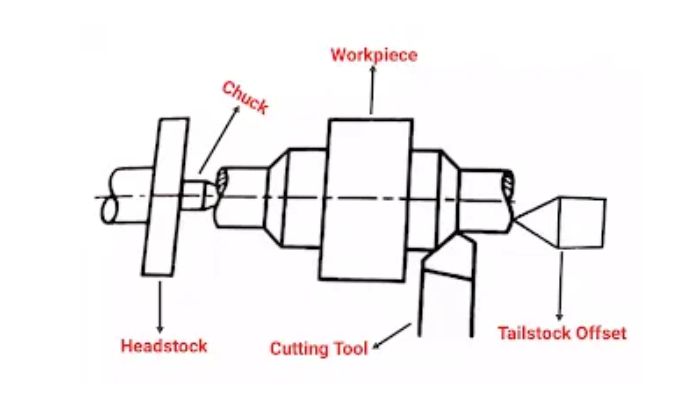

Tailstock Set Over Method

This method of taper turning is specifically employed for small top angles, and it is limited to machining external tapers. In this approach, the tailstock is intentionally misaligned based on the desired taper size. The clamping mechanism is loosened to facilitate offsetting, the upper part of the tailstock is adjusted as needed, and then the adjusting screws are tightened, as illustrated in the figure.

This method is also known as the Offsetting Tailstock method. In this technique, a ball center type work holding device is utilized in the tailstock. The amount of offset (O) is calculated using the formula:

\[ O = \frac{(Taper \times L)}{2000} \]

where \( O \) represents the offset, \( Taper \) is the desired taper, and \( L \) is the length of the taper.

Where,

0 = Offset, in mm.

Taper = millimeter/meter

L = Length of the workpiece in mm

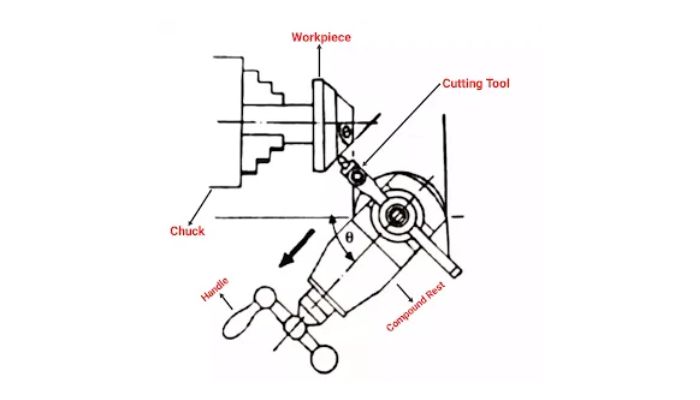

Compound Rest Method

Compound rest angle can be calculated by formula,

Tan θ = D-d/2L

θ = tan-1 (D-d/2L)

Where,

D = Larger diameter of the taper

d = Smaller diameter of the taper

L = Length of the taper

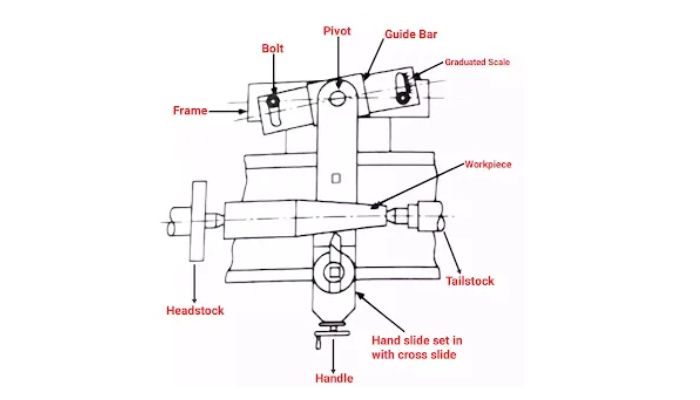

Taper Turning Attachment Method

The taper turning attachment is a supplementary tool that comes with contemporary lathes. Positioned behind the carriage, it is utilized for taper turning or boring without the need for tailstock offsetting. In this method, the job is secured between the centers or a chuck. When the job is held between the centers, only external taper turning can be accomplished. Refer to the figure depicting the taper turning attachment method.

The taper turning attachment comprises a frame affixed to the rear end of the lathe and a guide bar pivotally positioned at the center. The guide bar has the flexibility to swivel on either side at a 10° angle, and its position can be secured using two bolts. The workpiece for taper turning is set parallel to the lathe bed, typically between the centers, as depicted in the figure. The taper turning attachment ensures that the tool moves at a fixed angle during the turning process.

Parts of Planer Machine and Their Types, Operation, Mechanism

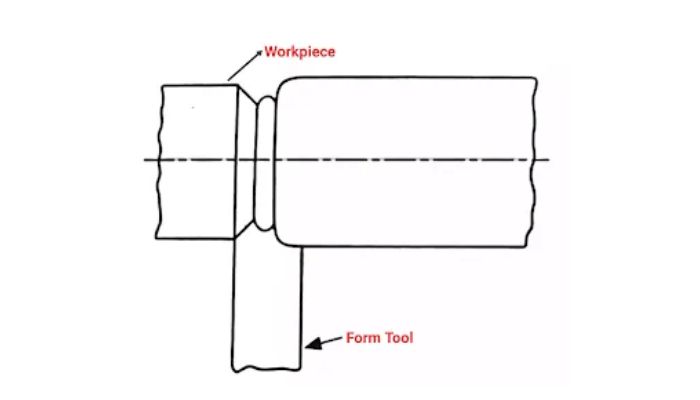

Form Tool Method

In this particular taper turning method, a straight form tool is employed, featuring a taper angle that aligns with the desired taper cutting edge.

Show in the figure,

This method involves providing a direct feed on the job, shaping it with a specific form. However, a drawback of this approach is that it doesn’t generate substantial force since a larger area comes in contact between the cutting edge and the workpiece. Consequently, this form tool method is primarily employed for short length tapers in taper turning.

Surface Grinding Machine Parts and Function,Types,Uses

Combining Feeds Method

In this method, both longitudinal and cross feeds are executed simultaneously, causing the tool to follow a diagonal path.

Methods of Measuring Tapers

There are six methods of measuring tapers in precision.

- By comparing the newly turned taper with a known taper.

- Using plug gauge for internal taper and ring gauge for the external taper.

- Using the taper test gauge.

- Using gauge blocks, test mandrel.

- Using sign bars and gauge blocks.

- Using a micrometer.

I’m glad you found the information helpful! If you have any more questions or if there’s anything else I can help you with, feel free to ask. Happy learning!

of course like your website but you have to check the spelling on several of your posts A number of them are rife with spelling issues and I in finding it very troublesome to inform the reality on the other hand I will certainly come back again