Hello, friends today we will learn reaming operation, In which you will learn all aspects related to reaming operation such as what is reaming operation, what is Reamers and their types as well as how to calculate reamer drill size?

Reaming operations are typically conducted using a drilling machine, and occasionally, they may be performed using a lathe machine. In modern times, these machines are often fully automated and operate through CNC machining.

The primary objective of a reaming operation is to achieve accurate sizing and a smooth finish in a pre-existing hole. (Rewrite United States language)

What is Reaming Operation?

A reaming operation is a cutting process used to refine the diameter and surface finish of an existing hole. It involves the use of a cutting tool known as a reamer. The primary purpose of reaming is to achieve precise sizing and a smoother surface in the pre-drilled hole. This operation is commonly performed on drilling machines and, in some cases, on lathe machines. Modern machining processes, particularly those involving CNC machining, have automated these operations for increased efficiency.

What is Reamer?

A reamer is a multi-point cutting tool designed for enlarging and refining the size of a previously drilled hole. It achieves a precise size and finish for the hole. The precision of the reamed hole can be influenced by factors such as speed, feed, and reaming allowance. Typically, the reaming speed is maintained at approximately half of the drilling speed. Reaming can achieve a high level of precision, ranging from -0.005 mm to +0.005 mm.

Reamers are commonly manufactured from materials such as carbon tool steel or high-speed steel. Additionally, carbide tip reamers are available, featuring carbide tips attached by brazing at the cutting edges.

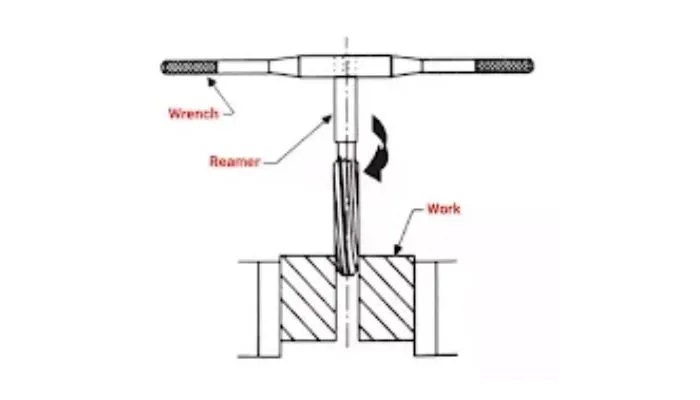

See in the figure that the reaming operation is performed with the help of reamers.

Types of Reamers

There are following two types of reamers are used.

- Hand Reamers

- Machine Reamers

Hand Reamers

Hand reamers have a square end that is used to remove metal up to 0.13 mm from the hole.

Read also: Types of Cutting Tool Materials and Their Properties

Machine Reamers

Machine reamers have a straight or taper end that is used under power.

Reaming By Hand

The following signs should be kept in mind while reaming by hand

- Clamp the job well in the vice.

- Check the reamer hole size which should be about 3% less than the size of the reamer.

- Place the reamer in the hole and check the vertical position.

- With light pressure, move the reamer clockwise.

- Use suitable coolant while reaming.

- Clean the reamer and job after reaming is complete and keep the reamer in its safe place.

Reaming by Machine

The following indications should be kept in mind while doing reaming by machine

- Clamp the job well on the table of the machine.

- Hold the reamer in place with the holder or adapter sleeve.

- Before starting, bring the reamer to the edge of the hole and feed it carefully.

- Use suitable coolant while reaming.

- Use the right speed. This is often less than the speed required for drilling so that the cutting edge does not overheat and deteriorate.

- Excessive feed should not be given.

- Clean the machine, reamer, and job after reaming is complete.

Precautions During Reaming Operation

- The reamer should be placed in a vertical position in the hole.

- The reamer should not be turned backward. Always use lard oil or any other suitable compound when reaming steel or wrought iron.

- Do not attempt to start the reamer on an uneven surface.

- From time to time, move the reamer upwards for reaming of the blind hole.

- Use a suitable reamer when reaming.

Formula for Calculating Reamer Drill Size

The following formula is used to calculate Reamer drill size.

R.D.S. = R.S. – (Under Size + Over Size)

Where,

R.D.S. = Reamer Drill Size

R.S. = Reamer Size

Undersize

The appropriate drill size is selected to obtain a reamer hole of a particular size.

It is called undersize.

This is an approved reduction in size as shown in the table below.

Read also: Tool Wear: Types, Factor Affecting, Causes and Remedies

| Sr. No | Diameter of Reaming Hole | Under Size of Rough Bore Holes |

|---|---|---|

| 1 | Up to 5 mm | 0.1 mm to 0.2 mm |

| 2 | 5 mm to 20 mm | 0.2 mm to 0.3 mm |

| 3 | 21 mm to 50 mm | 0.3 mm to 0.5 mm |

| 4 | Above 50 mm | 0.5 mm to 1.0 mm |

Oversize

Calculation of Reamer Drill Size

Question

Solution

So, friends, in this discussion, I covered the concept of the reaming operation, the role of reamers, the various types of reamers, the operational aspects of reaming, and the calculation of reamer drill size.

Read also: Manufacturing Process of Steel: 6 Methods of Making Steel

I trust you found this information engaging and that it provided a clear understanding of the various aspects related to reaming operations. If you have any queries or doubts, feel free to ask through comments or direct messages.

I appreciate your time and interest in this topic. Thank you.